The usage of force to move, lift, store, select, and retrieve goods over a short distance or a closed space in plants and factories is called material handling. Industries like agriculture, automotive, aerospace, construction, etc. use the material handling system.

There are 2 types of material handling. These are as follows:

- Manual Material Handling:

Manual Material Handling (MMH) involves physical labor to move, lift, store, and retrieve goods. Organizations heavily used this kind of handling before the invention of automatic handling.

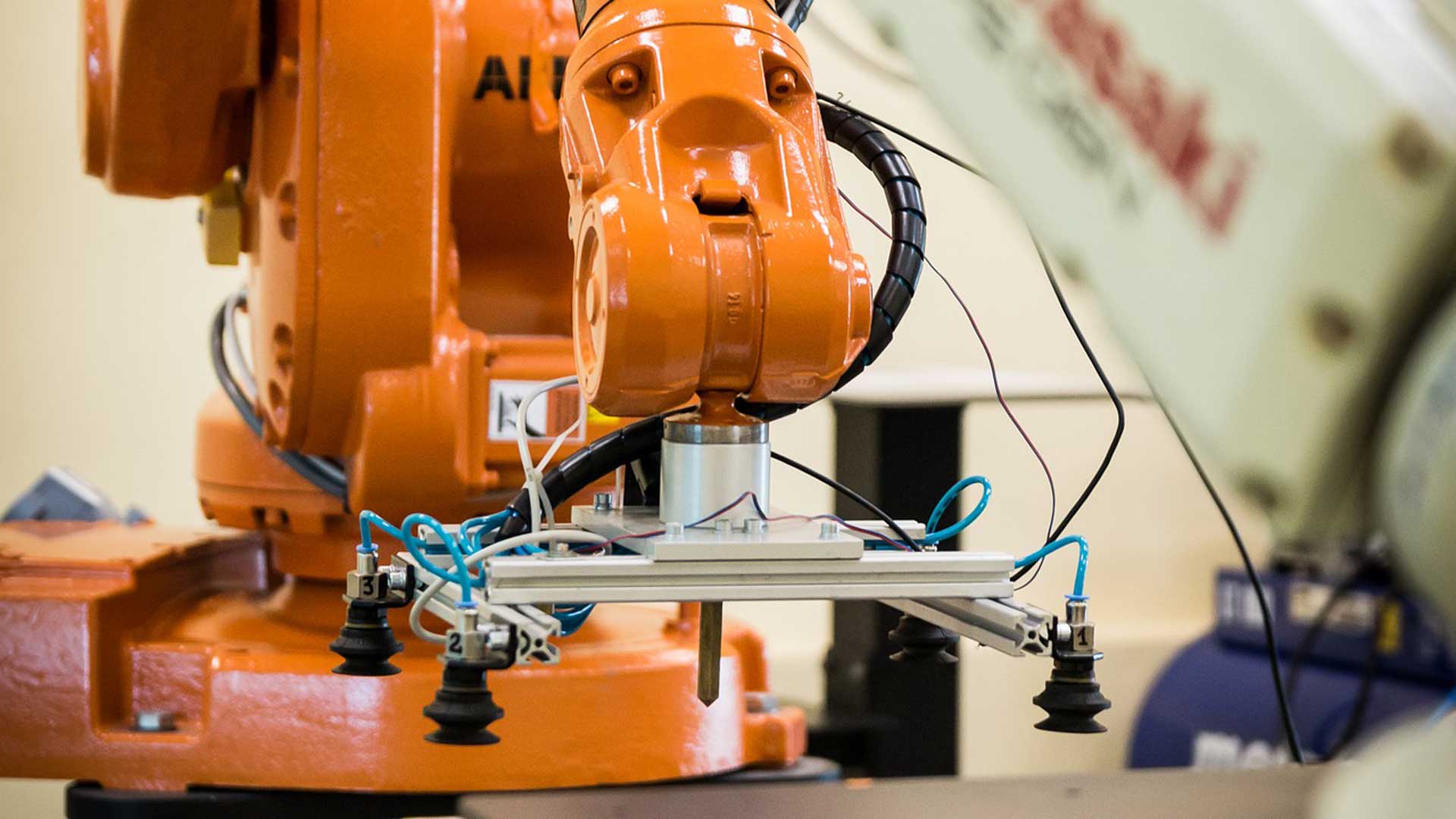

- Automated Material Handling:

Automated Material Handling (AMH) uses robots and other computer-based devices for moving and lifting. AMH may either involve single mechanical equipment or a set of devices like check-in tools, sorters, conveyors, unloading machines, trolleys, tote carriers, etc.

Benefits of Automated Material Handling

Today we will be discussing the benefits of Automated Material Handling:

1. High-Value Jobs

Nowadays, human/animal labor is not required because it takes a huge toll on them. Installing automatic technology will complement the workers and the job becomes easy and risk-free. It is found that automated handling helps the workers get high paying roles and values and ends up leaving repetitive tasks to the experienced taskers.

2. Better Data Accessing

Before automated handling was widely available, work areas and pieces of equipment in an industrial setting had to go through a lot of data. The automated systems sorted the problem by giving the logistic experts, facilities manager the power to access these data, and communication with them allow them to supervise a certain task.

3. Better Quality Control

The AI concept of handling machinery has gained a lot of thumbs-ups in the past few years. The concept is getting accepted globally with time and many big companies are already embracing the idea. Compared to labor-based handling, automated handling machines catch more errors and cut wasted and thus reduces extra work.

4. Better Workplace Safety

As described earlier, most employers are happy that with automation technology their safety concerns are almost eradicated. While some companies still work with manual handling this creates a safety concern for them. Switching to automation means all the health hazards can be prevented and thus creates a safer workplace for the employees. Installing automated robot handling can also benefit from doing a rather difficult and risky task at a very little time. This increases the efficiency of the workers.

5. Flexible Production

Automated handling equipment helps companies have flexibility across the operations. The supply chain and logistics managers, for example, have the opportunity to call upon data from a location. They can even use new commands to guide the vehicles and make adjustments to other equipment. By doing so they create a flexible production and systematics for their companies.

Conclusion

Automated handling has the upper hand when it comes to security, employees’ safety, and work efficiency. They get a job done in less time compared to manual handling. With progressive thinking, progressive steps should be applied to ensure the workplace is safe and profitable for any industry or company.